Birch Multiply Back in Stock

New stock has arrived of Latvian origin Birch Multiply.

Suitable for use in applications requiring a sturdy & flat panel.

B/BB Birch Multiply (edge)

21/03/24

What Happens to Plywood Outside?

Many people ask us if they can use plywood outside for walls and other applications.

It’s okay to use given it has an A-Bond Marine glue line, however it is subject to weathering as per the below photo.

So, if you would like to maintain the appearance, smooth plywood isn’t the best option when fully exposed, even when painted as per the below image on the left.

The face veneer can craze even if painted as the sun changes the moisture level in the top veneer leading it to expand and contract creating the lines you can see below.

If you want to use plywood outside and it maintain it’s appearance, we recommend the Shadowclad which is rough sawn (helps to prevent crazing) as well as it being treated.

With formply, which already comes with painted edges, if you are to cut the sheets as per the below photo on the right, we highly recommend that the edge is repainted as moisture

12/03/24

Which Ply Options Are Greenstar Certified?

Firstly, Greenstar is a sustainability rating & certification system. It recognises the use of legally sourced timber that are certified by a forest certification scheme such as FSC or PEFC via Green Star Timber Credits.

Second, the plywood options that meet this criterion include:

- Carter Holt Harvey (CHH) ECOPly, certified in accordance with FSC

- Austral Plywoods, certified in accordance with PEFC

The video below showcases the growing resource to be used later in the production of Austral Hoop Pine Plywood:

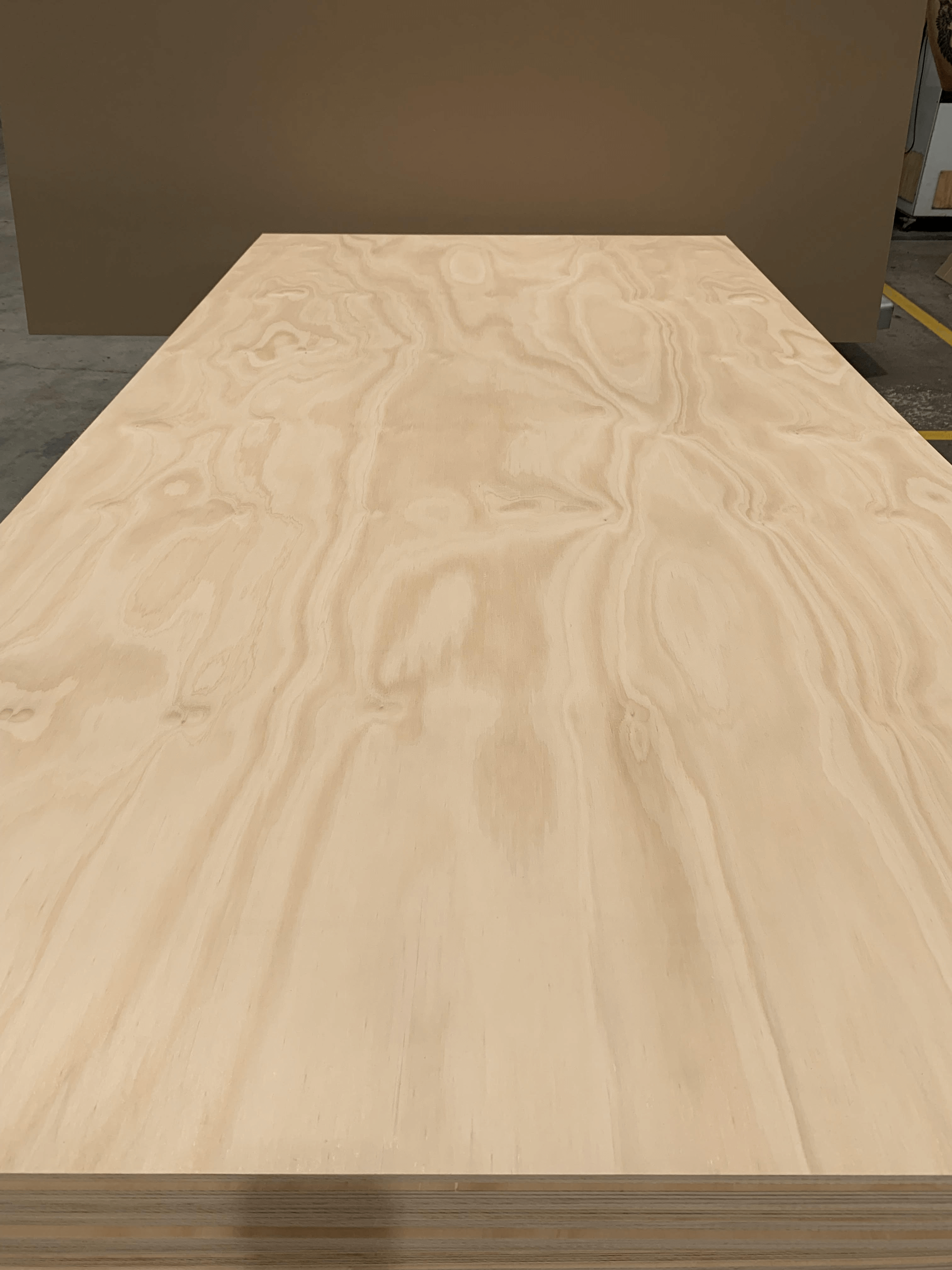

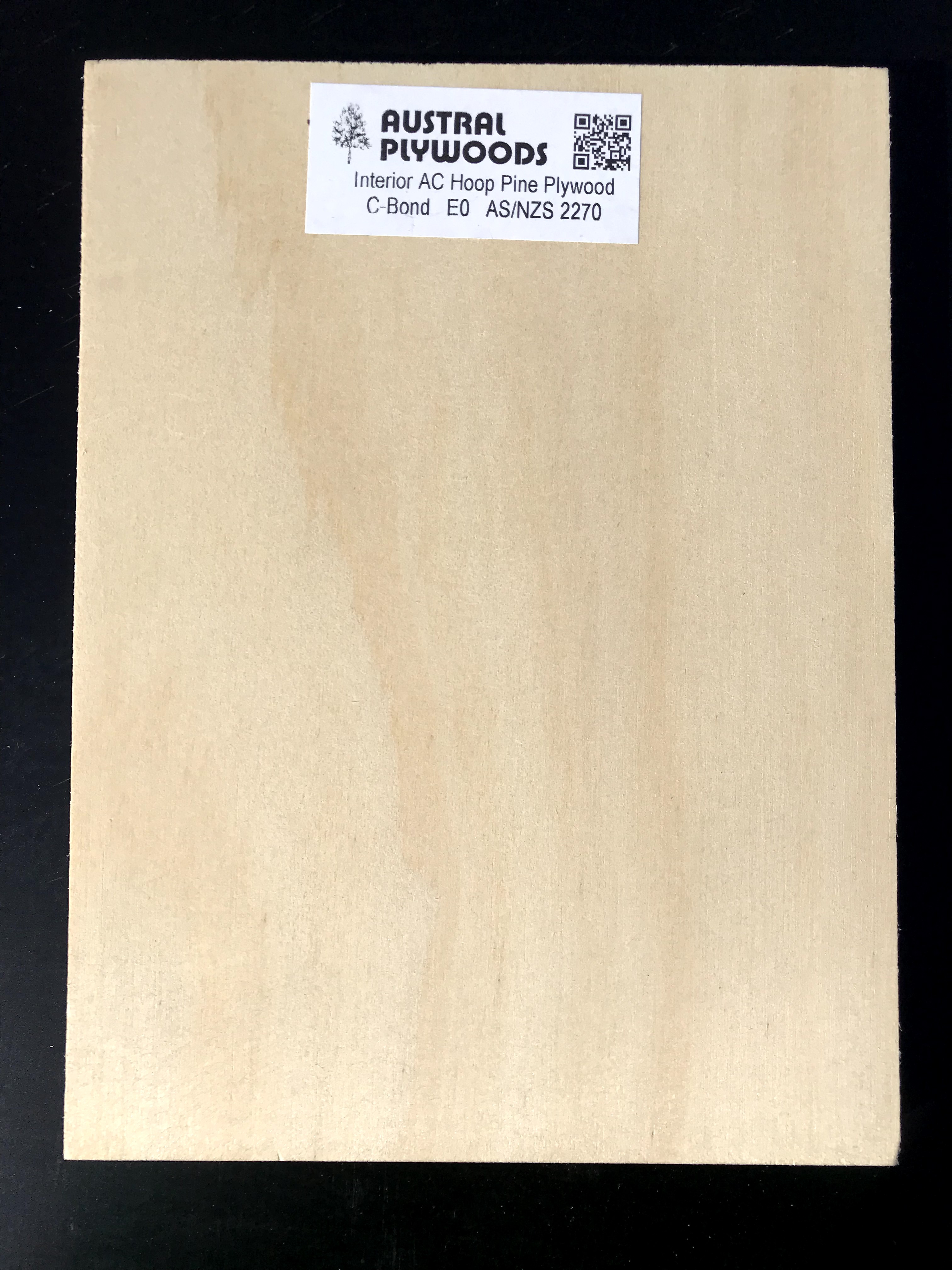

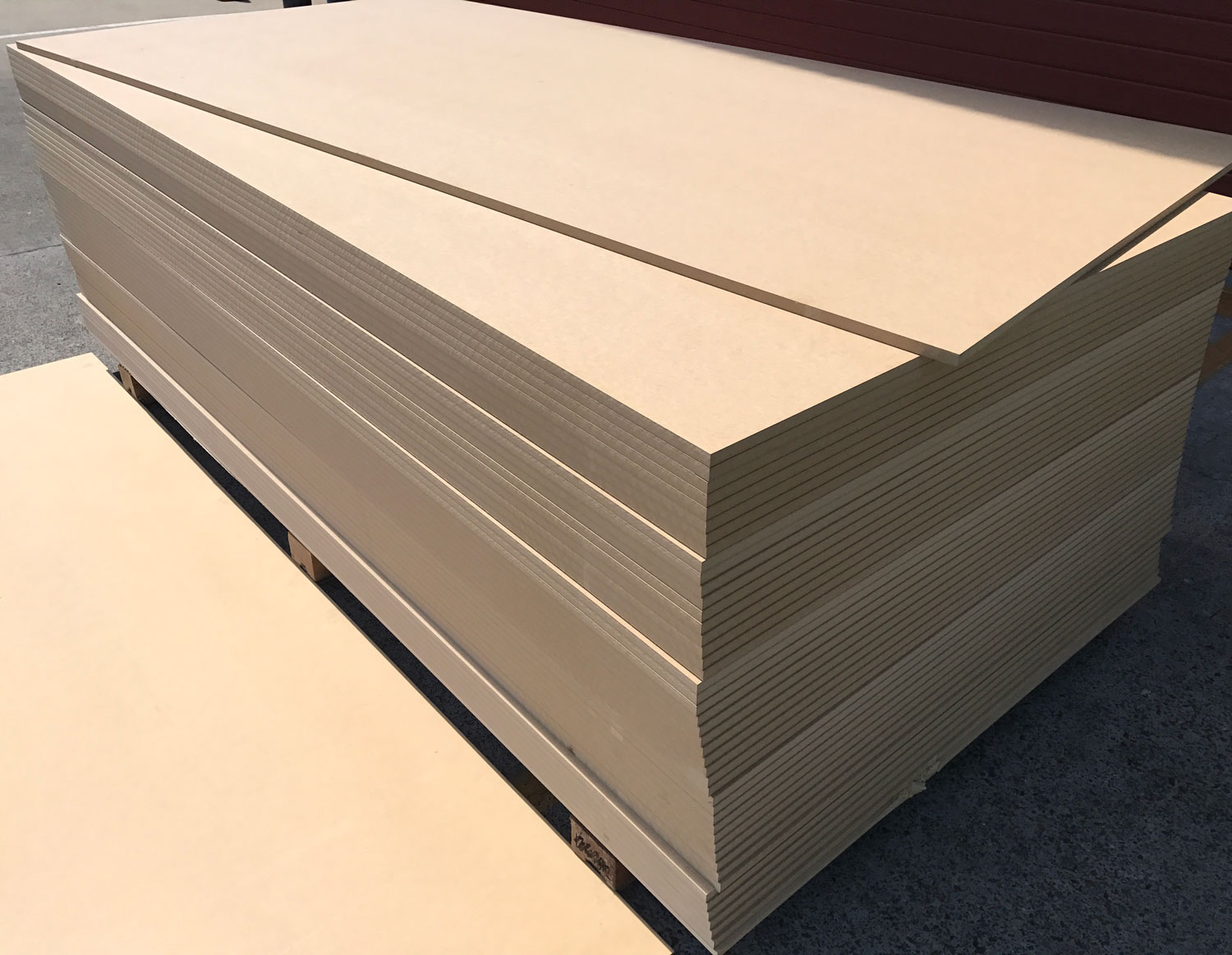

Ply for Laser Cutting

Yes, we do sell plywood suitable for laser cutting.

The 3mm & 4mm Austral Hoop Pine with C-Bond interior glue is the product offered.

The glue won’t flare up on the laser nor leave a charred edge.

We recommend the 4mm for added rigidity in comparison to the 3mm.

Please contact us for pricing on this Australian grown & made plywood.

16/05/23

4mm Plywood Options

Our most common thickness that customers request, here is a brief summary of the main 4mm plywood options, please contact us for pricing:

| Type | Features | Photo |

|---|---|---|

| DD Structural Brace Ply A-Bond | Flat, impervious durability & strong |  |

| BB/CC Basswood Hardwood | Flat & decent in appearance |  |

| AC Interior Hoop Pine | Interior grade, suitable for Laser Cutting |  |

16/05/23

12mm Plywood Options

Our most common thickness that customers request, here is a brief summary of the main 12mm plywood options, please contact us for pricing:

| Type | Features | Photo |

|---|---|---|

| CD Non-Structural Pine Plywood | Economical |  |

| CD Structural Hardwood A-Bond | Flat, impervious durability & strong |  |

| BB/CC Hardwood A-Bond | Flat, durable & decent in appearance |  |

| BB Structural Hoop Pine A-Bond | Durable, marine specie & decent in appearance |  |

19/04/23

Sustainable Forestry

Sustainable forestry is a vital cause to us here at Plywood and Panel. At first, hearing the words ‘sustainable’ and ‘forestry’ together might seem like an oxymoron; however, with careful planning, certain harvesting methods, and an active commitment to achieving the highest ecological, social, and ethical standards, the words can accurately co-exist.

In Australia, Responsible Wood pioneered the development of certification standards and schemes to ensure that any and all forest-based products are harvested, produced, and supplied with the highest respect for ecological, social, and ethical standards. Covering more than 90% of Australia’s forests, Responsible Wood’s certification scheme is the leading mechanism that provides guidance and accountability to forest managers, manufacturers and suppliers. The question still remains, what methods actually ensure sustainable forestry?

Sustainable harvesting methods such as Variable Retention Harvesting (VRH) ensure the necessary balance of ecological, social and ethical impacts.

What do these methods comprise of? Well, let’s first take a look at Variable Retention Harvesting (video below). VRH is a unique harvesting method that ensures the continuation of young and mature trees. Extensive planning goes into this process to ensure that biodiversity is maintained for the continued health of forest’s ecosystems. Essentially, this harvesting method emulates natural disturbances to ensure – as the name suggests – retention of the natural model of a forest which suits the whole suite of organisms and species residing within.

17/03/2023

Oversized Plywood

A common question we get asked is do we stock any oversized plywood sheets? The answer is yes! Suited for both interior and semi-exposed exterior applications, our Gaboon Hardwood range is the perfect option if you’re after oversized sheets with strength and good appearance.

For available sheet size and thickness, please see the specifications below.

Specifications

| Length x Width (mm) | Thickness (mm) | Sheet Weight (Kg's) |

|---|---|---|

| 2440 x 1530 | 6 | 13.7 |

| 2440 x 1530 | 9 | 20.5 |

| 2440 x 1530 | 12 | 27.3 |

| 2440 x 1530 | 15 | 34.2 |

| 2440 x 1530 | 18 | 41.0 |

| 3050 x 1220 | 3.6 | 8.2 |

| 3050 x 1220 | 6 | 13.6 |

| 3050 x 1220 | 9 | 20.2 |

| 3050 x 1220 | 12 | 27.2 |

| 3050 x 1220 | 15 | 34.0 |

| 3050 x 1220 | 18 | 40.9 |

| 3050 x 1220 | 25 | 56.7 |

| 3050 x 1530 | 3.6 | 10.2 |

| 3050 x 1530 | 6 | 17.1 |

| 3050 x 1530 | 9 | 25.6 |

| 3050 x 1530 | 12 | 34.2 |

| 3050 x 1530 | 15 | 42.7 |

| 3050 x 1530 | 18 | 51.2 |

| 3050 x 1830 | 12 | 40.9 |

| 3050 x 1830 | 18 | 61.3 |

16/02/2023

Tom Robinson

Twenty-three-year-old Brisbane local, Tom Robinson, is currently attempting to do what most what consider impossible: a solo row across the Pacific Ocean from South America to Australia. As if this world record breaking attempt isn’t impressive enough, Tom is completing this journey in his self-built rowboat, Maiwar.

Maiwar, an indigenous word for Brisbane River is a testament to Tom’s roots – having spent much of his youth rowing the river. Tom’s dedication to rowing began in the Brisbane River, having rowed to and from school and it didn’t stop there. At a mere fourteen years of age, Tom rowed from Brisbane to the Gold Coast solo.

Having approached us in the very early stages of planning, we recommended he speak directly with Austral Plywoods. Like so many others, we have loved keeping up with Tom’s journey through his Blog.

Maiwar is a 7-metre-long rowboat designed and constructed by Tom using Austral Marine Plywood. The build, which took five months, was based on a traditional whaleboat design. Check out the early stages of the build below:

You might think crafting the vessel out of Plywood to be an unusual choice, seeing as though the boat is expected to be at sea for some twelve plus months. However, for Tom there was no other choice. We commend Tom for his commitment to sustainability when planning his build, choosing sustainable Queensland-grown plantation Hoop Pine rather than less environmentally friendly materials such as plastic or carbon fibre.

View more impressive images from Tom’s trek below and make sure to subscribe to his website for updates and to track his record-breaking progress.

09/02/2023

Standard versus Moisture Resistant MDF

A common question we get asked is: What is the difference between Standard and Moisture Resistant MDF? Though both panels share some benefits, such as a uniform finish and smooth surface, moisture resistance is not one of these shared benefits. As the name suggests, the Standard panels do not provide protection against humidity and accidental wetting like their Moisture Resistant counterparts and consequently, what panel is best for you will depend on the application.

What creates the difference between the panels?

The primary factor that creates this difference is the resin used in the manufacturing process. Unlike Standard panels, Moisture Resistance panels utilise a specially formulated water-resistant resin, making it the perfect option for applications such as kitchen cabinets, bathroom vanities, or laundry cupboards. For other interior applications that are not exposed to high humidity or damp conditions, such as wall linings or furniture, the Standard MDF panels are suitable.

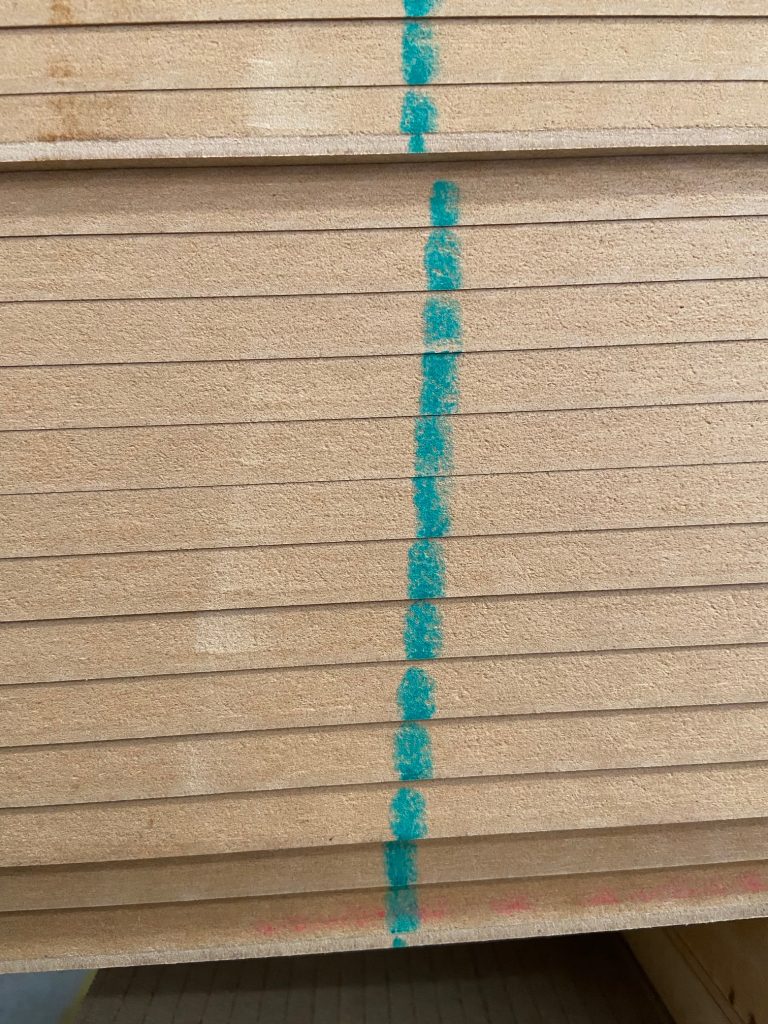

How to tell the difference between MDF and MDFMR?

For Standard MDF, an orange chalk line runs down one long side close to the edge and for Moisture Resistance MDF, a green chalk line does the same.

07/02/2023